Solutions Backed by Service

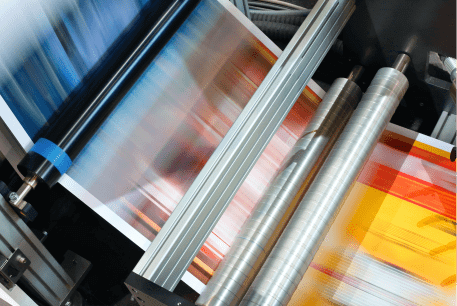

Automate and simplify your organization’s workflow with our wide range of reliable automation solutions. Our next-generation equipment paired with world-class service helps increase efficiency, cut costs, and improve your production workflows.